Rapid innovation as a competitive advantage

The high-wage state of Germany and the state of Baden-Württemberg owe much of their prosperity to the ability of their medium-sized industry to quickly and repeatedly bring innovative products to the world market. In doing so, it is crucial to permanently maintain a scientific and technological lead over international competitors and potential imitators.

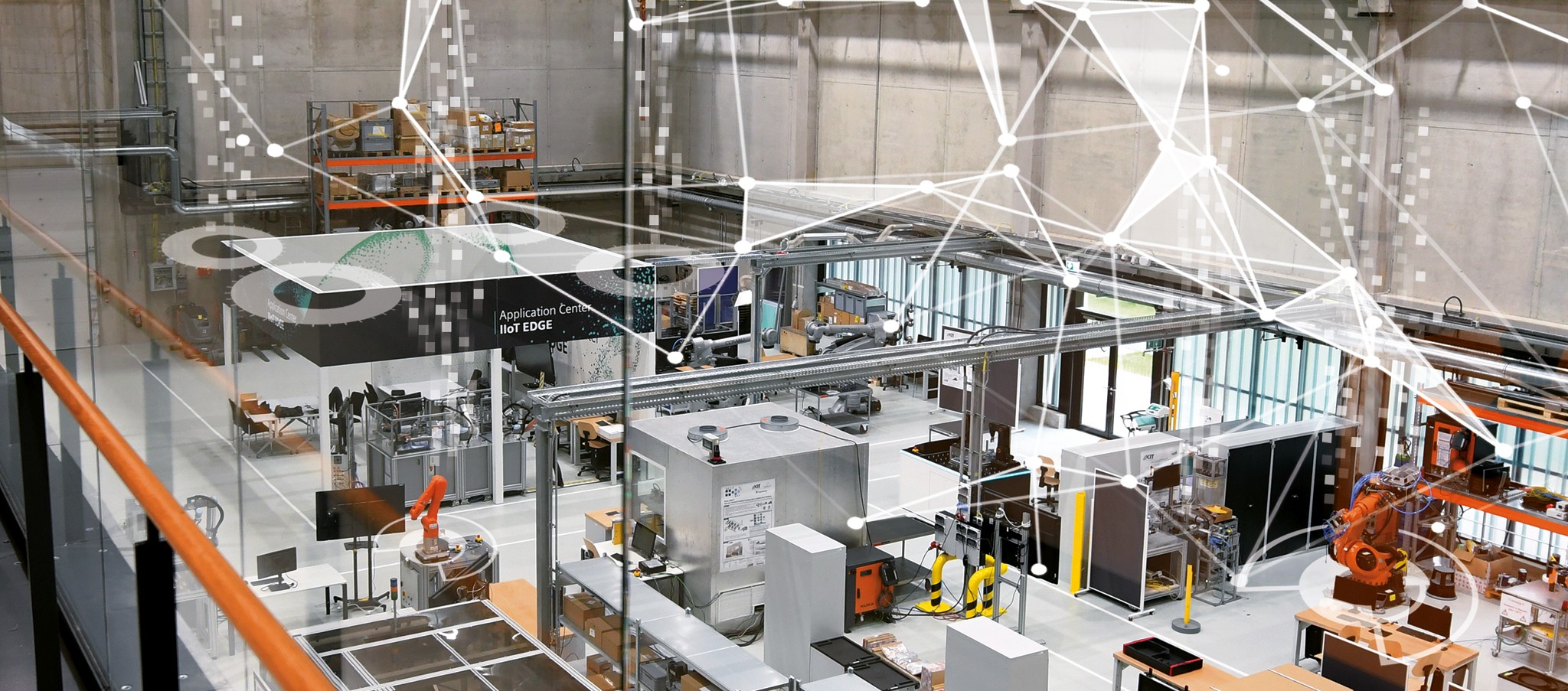

The world in which we live and work is not stable, but volatile. Agile, versatile production concepts and the rapid empowerment of processes have the potential to sustain value creation in Baden-Württemberg in the long term.

Prof. Dr.-Ing. Jürgen Fleischer, Head of the wbk Institute Production Technology at KIT

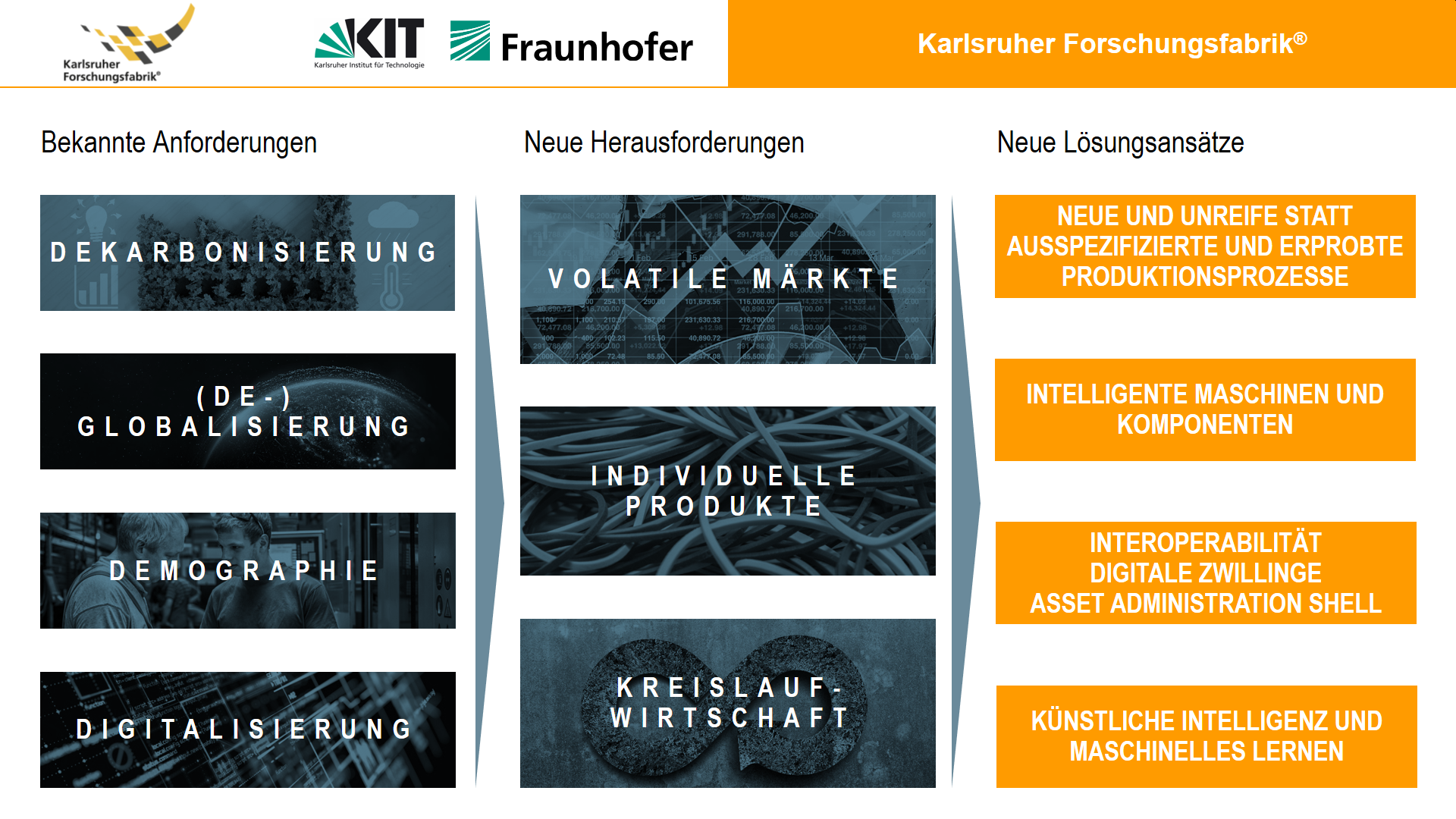

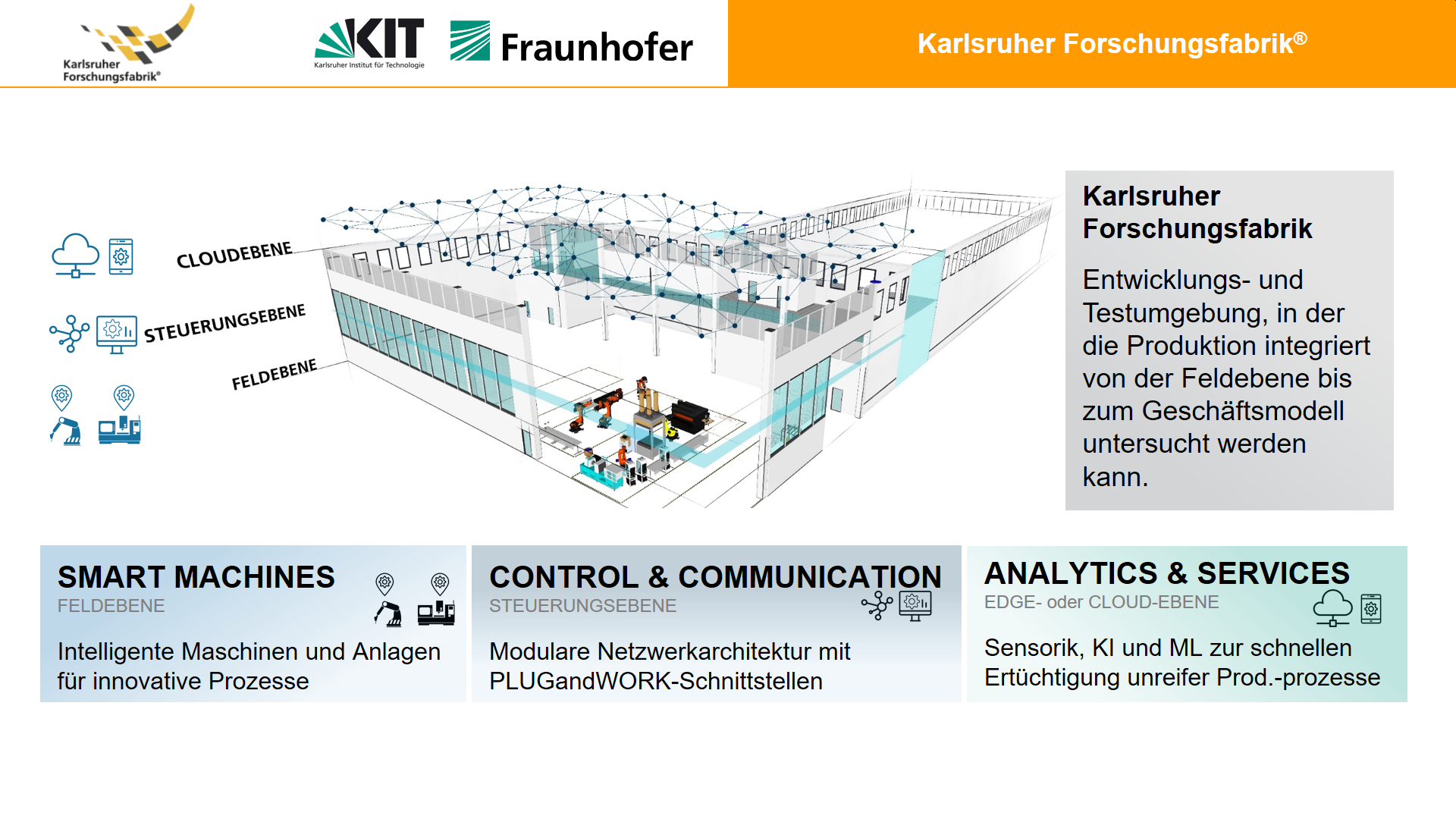

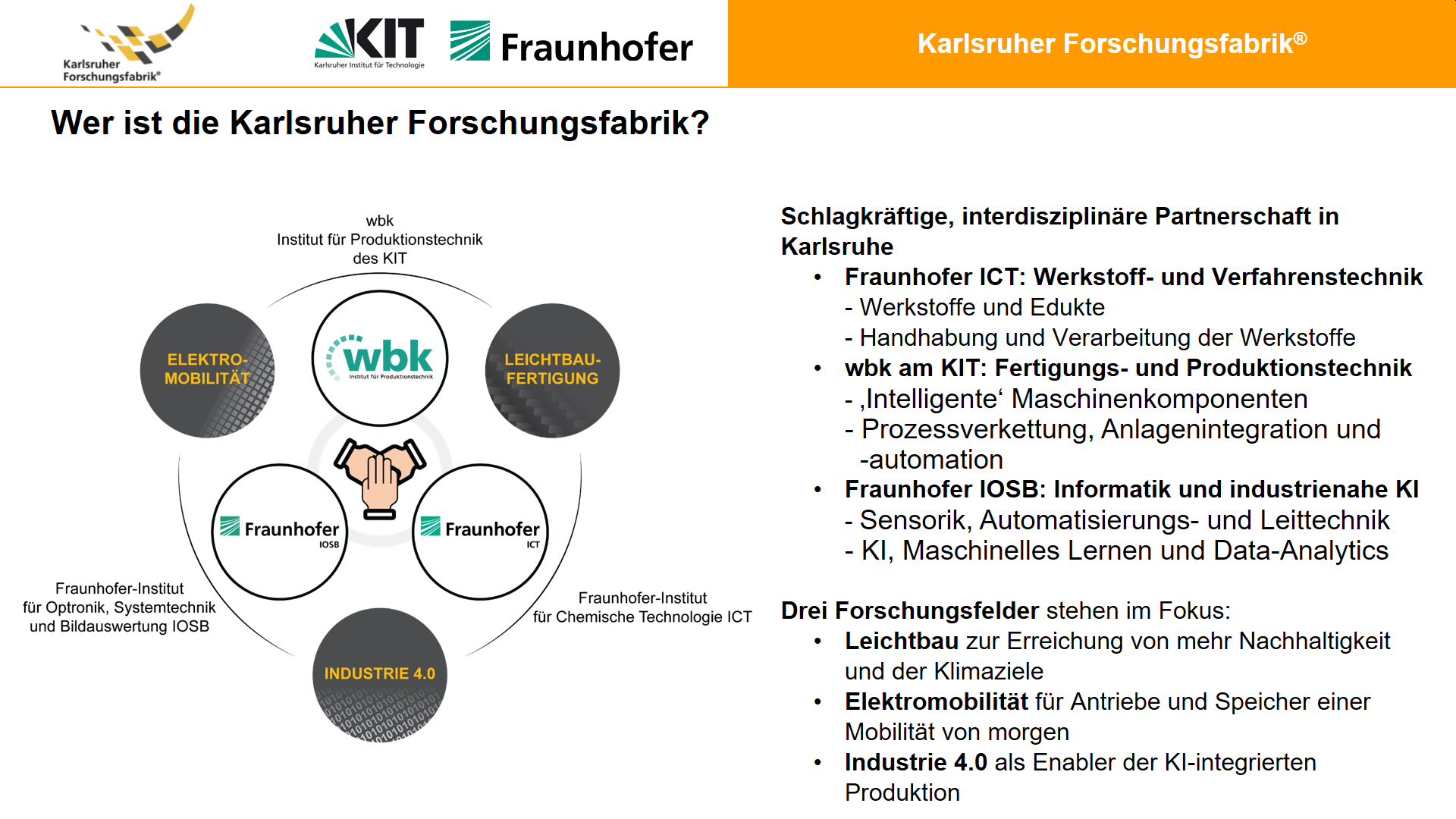

Using the approach of AI-integrated production, the Karlsruhe Research Factory aims directly at systematically developing and expanding such advantages in new, challenging manufacturing processes. The starting point is the increasingly frequent observation that engineers and production planners no longer completely specify new production processes as before. Instead, it must be possible to produce high-quality new products while the manufacturing processes themselves are still being developed.

Karlsruhe Research Factory

Karlsruhe Research Factory