A crash course for professionals and managers

What is AI? How does it enter production? Learn the basics of Machine Learning and Artificial Intelligence in production – technically sound and based on concrete use cases and demonstrators. The course is free and consists of interactive materials that can be worked through independently.

After the course, you will have an overview of the opportunities and possibilities, have a feeling for the effort involved in corresponding projects, and know the basic tools for tackling ML problems yourself, which will make it easier to collaborate with ML experts in particular.

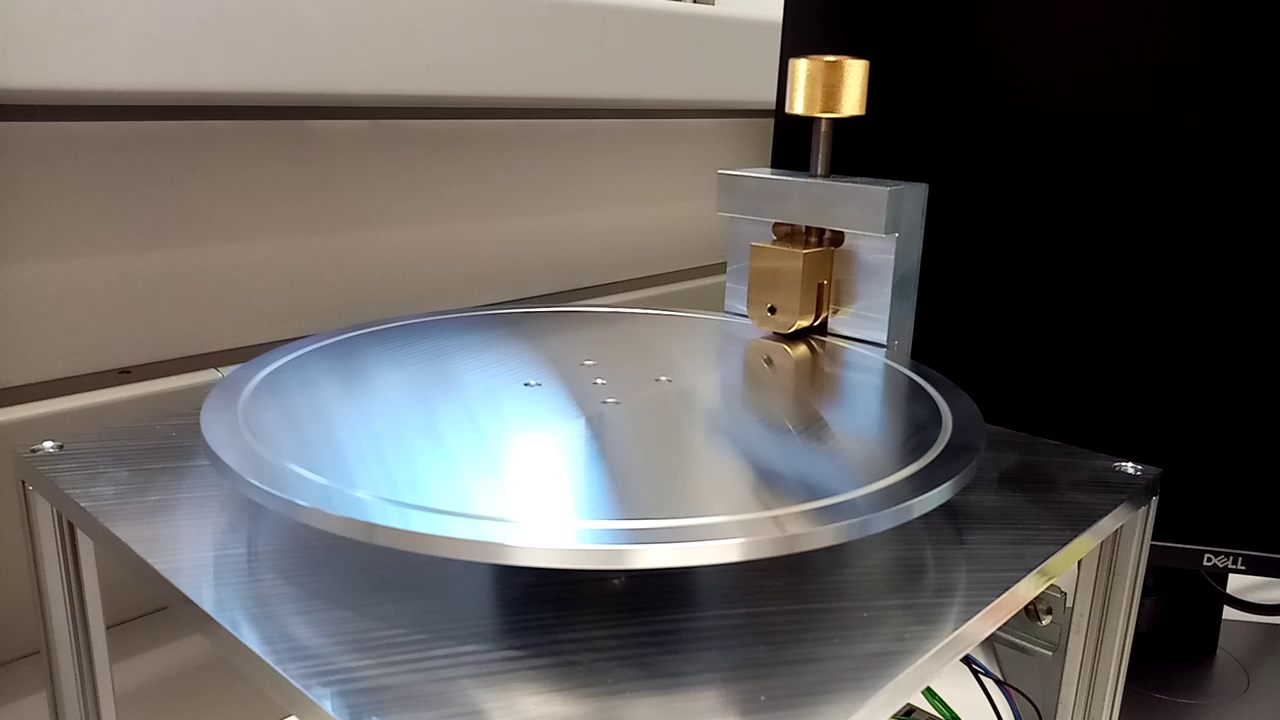

Karlsruhe Research Factory

Karlsruhe Research Factory